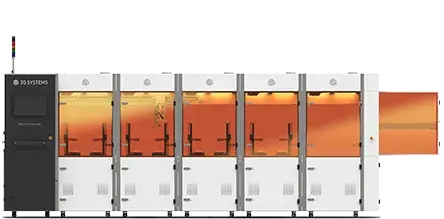

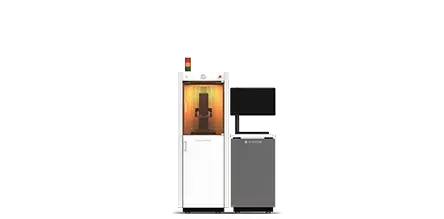

La fabricación redefinida

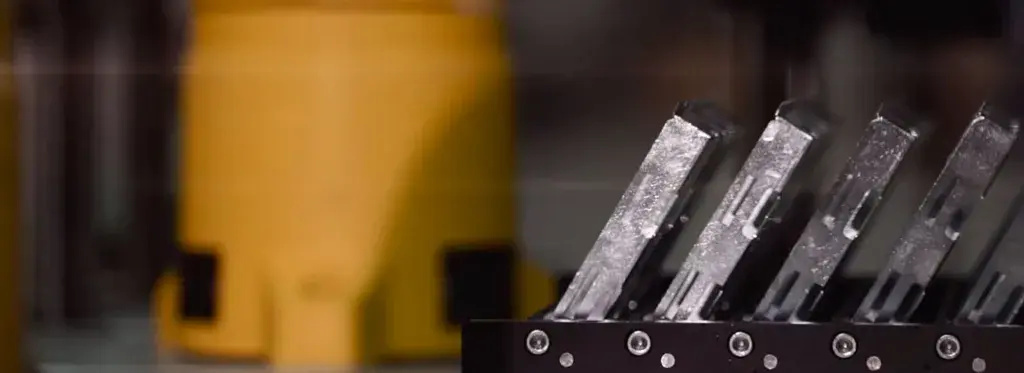

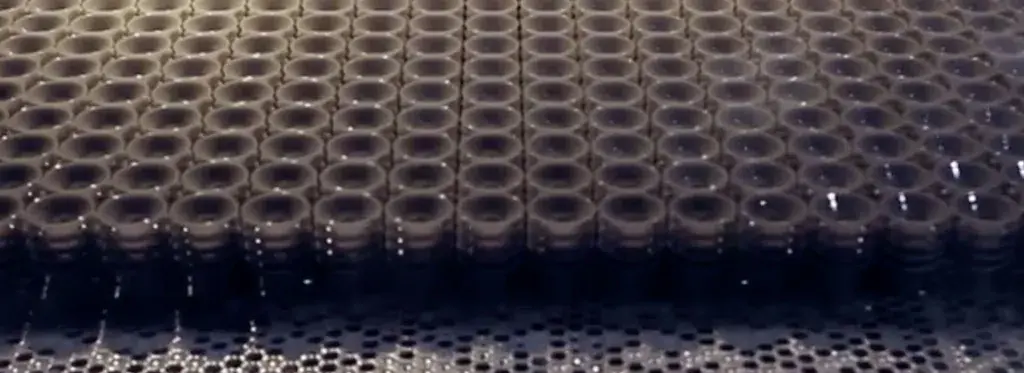

La Figure 4 de 3D Systems hace realidad la producción 3D y, como consecuencia, se logra una mayor productividad, durabilidad, capacidad de reproducción y un menor costo total de las operaciones (TCO). Ofrece productividad a través de la velocidad y la automatización de piezas reales, repetibles y precisas que tienen rendimiento Six Sigma demostrado en un amplio rango de materiales de producción resistentes.