Please register here to watch the recording

Thanks to new materials, faster print speeds, and innovative workflows, additive manufacturing (AM) is transitioning from its primary use as a prototyping tool to an efficient and productive option for scaled manufacturing that is competitive with traditional manufacturing methods like injection molding. And because additive manufacturing offers greater supply chain flexibility and fast part turnaround, it is a uniquely strong solution for low-volume and bridge manufacturing, as well as mass customization.

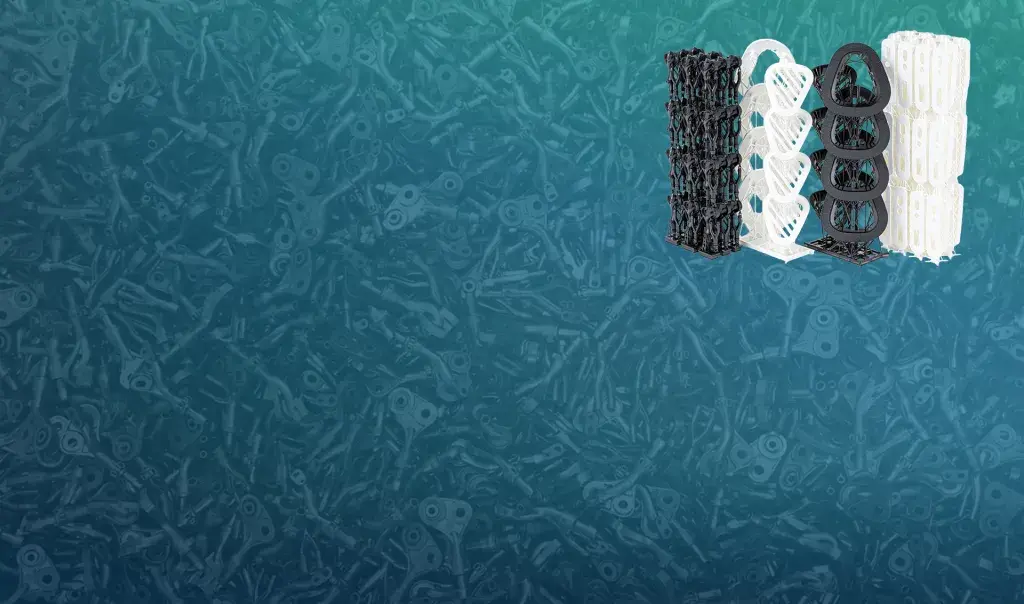

3D Systems is excited to share a major advancement in build efficiency with our new solution for high density part stacking that takes advantage of the build height of Figure 4 printers, efficient nesting, and optimized support structures to enable greater levels of batch printing and post-processing.

Topics covered in this webinar include:

- Background on batch production with existing technologies

- Challenges for production capabilities with Figure 4

- Advantages of the new stacked workflow

- Demonstration of the new 3D Sprint solution

Join us for our webinar to learn how advancements in high density stacking on our Figure 4 solution are advancing productivity for additive manufacturing to deliver thousands of production parts in just 48 hours.