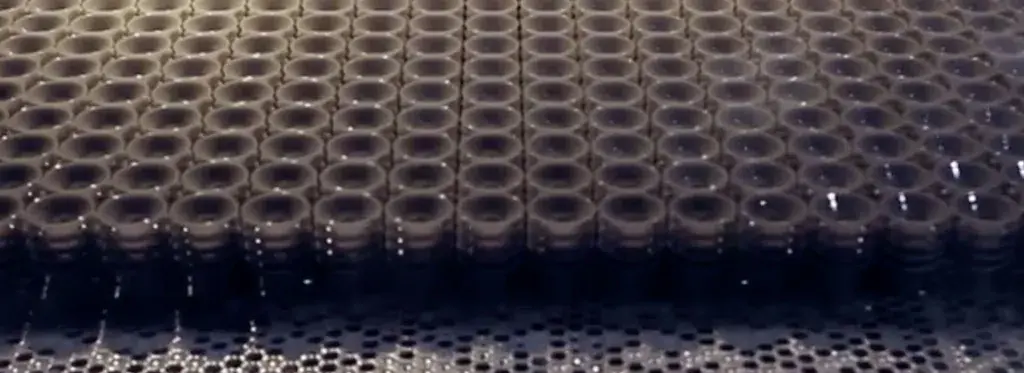

Proven Performance in Extreme Conditions

Impresoras compatibles con este material:

Figure 4 135

Alta velocidad, alta precisión con exactitud repetible para la fabricación sin herramientas

Figure 4 Standalone

Ultra rápido y asequible para la creación de prototipos en el mismo día y bajo volumen de producción

Figure 4 Production

La primera solución de la industria que se puede personalizar y que está completamente integrada para la producción directa de fábricas

Figure 4 Modular

Solución de fabricación 3D escalable y semiautomatizada diseñada para escalar junto con su crecimiento

Soporte